Mongabay Series: Bioenergy, Covering the Commons, Planetary Boundaries

by Justin Catanoso on 20 November 2023

- The forest biomass energy industry took a major hit this month, as Enviva, the world’s largest producer of wood pellets — burned in former coal power plants to make energy on an industrial scale — saw catastrophic third quarter losses. Enviva’s stock tanked, its CEO was replaced and the company seems near collapse.

- Founded in 2004, Enviva harvests forests in the U.S. Southeast, with its 10 plants key providers of wood pellets to large power plants in the EU, U.K., Japan and South Korea — nations that use a scientifically suspect carbon accounting loophole to count the burning of forest wood as a renewable resource.

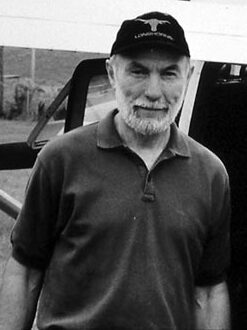

- A former manager and whistleblower at Enviva told Mongabay in 2022 that the company’s green claims were fraudulent. Last week, he said that much of Enviva’s downfall is based on its cheaply built factories equipped with faulty machinery and on large-scale fiscal miscalculations regarding wood-procurement costs.

- How the firm’s downfall will impact the global biomass for energy market, and worldwide pellet supply, is unknown. European and Asian nations rely on Enviva pellets to supply their power plants and to meet climate change goals, with the burning of forests to make energy erroneously claimed as producing zero emissions.

This year has been a financial disaster for Enviva, the world’s largest producer of wood pellets for the biomass energy industry. With more than $250 million in losses to date and worsening results expected in the fourth quarter, the once high-flying company’s viability, by its own admission, is in grave doubt.

Also in question is where Enviva’s European Union and Asian customers will source the pellets they burn in their converted coal power plants and — without those pellets — how nations will meet their energy needs and their pledged Paris Agreement carbon emission cuts.

To many financial analysts who closely follow company performance, Enviva’s near collapse this month appears to have happened rapidly and suddenly. But did it?

“The problems have been there for years. There are lots of issues, but they stem from fundamental challenges Enviva faces in wood costs and keeping its manufacturing plants operating at full capacity,” a former Enviva maintenance manager told Mongabay. “It’s all coming home to roost in a kind of cumulative way.”

In exclusive interviews with Mongabay, the former Enviva employee detailed critical problems he witnessed and grappled with as a top operations manager at two of Enviva’s 10 Southeast U.S. plants between mid-2020 and mid-2022. His insights help explain why Enviva is now in dire financial straits.

Small mountains of forest wood, ch ipped from whole trees and loaded into tractor-trailers for delivery, are piled up outside the Enviva wood pellet mill in Ahoskie, North Carolina. According to a former Enviva maintenance manager and whistleblower at the company’s plants in North and South Carolina, the mix of wood Enviva uses is 80% pine and 20% hardwood. Pine is cheaper for Enviva to purchase, but it has a quick and corrosive impact on pellet-making machinery, leading to production slowdowns and shutdowns, and very high maintenance costs, the source told Mongabay. Image by Justin Catanoso.

ipped from whole trees and loaded into tractor-trailers for delivery, are piled up outside the Enviva wood pellet mill in Ahoskie, North Carolina. According to a former Enviva maintenance manager and whistleblower at the company’s plants in North and South Carolina, the mix of wood Enviva uses is 80% pine and 20% hardwood. Pine is cheaper for Enviva to purchase, but it has a quick and corrosive impact on pellet-making machinery, leading to production slowdowns and shutdowns, and very high maintenance costs, the source told Mongabay. Image by Justin Catanoso.

In a Dec. 5, 2022, Mongabay story that reverberated globally, this Enviva whistleblower was the first insider from the multibillion-dollar international wood pellet industry to ever go public. At the time, he accused Enviva of falsifying its green claims and not being truthful about where and how it sourced forest wood for the tons of pellets it makes every day in the U.S. for export.

“The company says that we use mostly waste like branches, treetops and debris to make pellets,” the whistleblower told Mongabay a year ago. “What a joke. We use 100% whole trees in our pellets. We hardly use any waste. Pellet density is critical. You get that from whole trees, not junk.”

But junk wood is cheap, while whole trees are not, and therein lies a part of Enviva’s operational problems.

The former employee — who declined to be named to protect his professional and family’s privacy — said last week that this wood-sourcing deception is one reason Enviva has been losing money.

“Enviva built a business model saying it uses mostly scrap and waste from lumber mills and cut sites to make its pellets,” he said. “If that were true, its feedstock would basically be free. But it has to buy trees, a lot of trees, and it’s competing for them with other companies that want that wood. Loggers sell to the highest bidder, right, and that drives up the price. It’s something Enviva can’t control.”

In its 2023 third quarter filing on Nov. 9 with the Securities and Exchange Commission, Enviva wrote that among the myriad reasons impacting its financial viability is “the amount of low-cost wood fiber that we are able to procure and process.”

“So that’s your first problem,” the former employee said. “Your feedstock is costing way more than you’re letting on, and that’s before you start dealing with the costs of making pellets.”

Enviva did not respond to multiple requests from Mongabay for comment.

Mongabay contributor Justin Catanoso spent an afternoon in November 2022 on a 52-acre formerly wooded site in Edenton, North Carolina, being cleared in part for Enviva feedstock. While the company claims it uses mostly wood scraps and treetops for its pellets, Catanoso witnessed whole trees being chipped for Enviva and loaded into a tractor-trailer for delivery to the company’s nearby plant in Ahoskie. Limbs, treetops and wood waste, seen in the foreground, were left behind. Enviva’s publicly trumpeted manufacturing model claims to use cheap wood waste to make pellets; instead, the company uses expensive whole trees, resulting in cost overruns. Image by Justin Catanoso.

Tracking the collapse

For Maryland-based Enviva, 2022 looked to be a financial launchpad for future growth. Revenue topped $1 billion for the second year in a row, up 24% from two years prior. Its stock price hit a peak of $87 per share in April 2022. New multiyear contracts were locked in with taxpayer-subsidized customers across the European Union, United Kingdom, Japan and South Korea as the firm dominated the global market for wood pellets used by the energy industry.

Enviva boldly predicted it would double wood pellet output, from 6.2 million metric tons shipped overseas in 2022, to 13 million metric tons by 2027. With 10 pellet mills operating between southern Virginia and the Gulf Coast, the company secured a $570 million line of credit to build its biggest plants yet in Alabama and Mississippi, which have been under construction.

Enviva could even afford to ignore its persistent global critics, forest advocates who argue the company is increasing deforestation amid the climate crisis by exploiting a renewable-energy policy loophole overseas that — with little scientific validity — designates wood burning as a renewable, carbon-neutral substitute for coal.

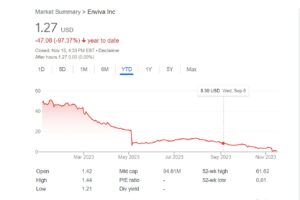

The company was on a steady upward trajectory since its founding in 2004. But cracks in the corporate façade broke wide open May 3 of this year in reporting of its first quarter results. Wall Street analysts, who were bullish on Enviva stock at the time, were stunned when the company lost $117 million between January and March, three times worse than it forecasted. Enviva canceled its shareholder dividend, a red flag for a company in distress. Its declining stock price plunged in hours from $21 to less than $8.

Enviva’s stock collapse this year: The company’s stock was trading above $51 per share on January 13, 2023, and gradually slid to half that until the May 3 plunge. It dived again on November 9, bottoming out at 62 cents per share that day, and has not recovered much value since. It is now trading as a penny stock. Source: November 16 end of day trading screenshot from Google.com.

Enviva’s stock collapse this year: The company’s stock was trading above $51 per share on January 13, 2023, and gradually slid to half that until the May 3 plunge. It dived again on November 9, bottoming out at 62 cents per share that day, and has not recovered much value since. It is now trading as a penny stock. Source: November 16 end of day trading screenshot from Google.com.

In a conference call, CEO Thomas Meth made a passing reference to operational challenges at Enviva’s plant in Southampton, Virginia — challenges he said were a priority to address.

Things got far worse for Enviva, and Meth, on Nov. 9 with Enviva’s third quarter results. Another $85 million lost, four times more than third quarter losses in 2022. The stock price, which had climbed above $13 in August, plunged to 61 cents as major shareholders dumped their shares. The company acknowledged it had exhausted its $570 million line of credit used for construction of those plants in Alabama and Mississippi, casting those projects in doubt.

Meth was demoted from CEO to president, and Enviva made this startling admission: “The conditions and events in the aggregate raise substantial doubt regarding the company’s ability to continue as a going concern.”

Glenn Nunziata, who had joined Enviva just three months ago as chief financial officer, was named interim CEO. In a conference call to investors on Nov. 9, Nunziata also referenced the Southampton plant, saying it had improved its operating costs by shutting down half of the manufacturing lines that make pellets.

The former Enviva maintenance manager told Mongabay he knew why.

This aerial view of Enviva’s wood pellet production mill in Ahoskie, North Carolina, pictured in fall 2022, shows the large conveyors and chains in the background that move pine and hardwood chips into dryers to pull the moisture out of the wood before it is pressed into pellets roughly the size of medicine capsules. According to a former Enviva maintenance manager, those conveyors and chains are composed of carbon steel, which corrodes and rusts quickly when exposed to moisture, especially from drying resinous pine. This causes frequent and costly facility shutdowns and delays, which has contributed to Enviva losing millions of dollars over the past two years due to maintenance and manufacturing costs per ton of wood pellets made, creating a huge loss for the company as it sells pellets under fixed-price contracts. Image courtesy of the Dogwood Alliance.

This aerial view of Enviva’s wood pellet production mill in Ahoskie, North Carolina, pictured in fall 2022, shows the large conveyors and chains in the background that move pine and hardwood chips into dryers to pull the moisture out of the wood before it is pressed into pellets roughly the size of medicine capsules. According to a former Enviva maintenance manager, those conveyors and chains are composed of carbon steel, which corrodes and rusts quickly when exposed to moisture, especially from drying resinous pine. This causes frequent and costly facility shutdowns and delays, which has contributed to Enviva losing millions of dollars over the past two years due to maintenance and manufacturing costs per ton of wood pellets made, creating a huge loss for the company as it sells pellets under fixed-price contracts. Image courtesy of the Dogwood Alliance.

Wood pellets on the cheap: Pine meets carbon steel

When Enviva built its first plants — four in eastern North Carolina along with the one in Southampton, Virginia — the goal was to contract with local loggers to supply 80% hardwoods and 20% pine. That mix proved unsustainable.

“Enviva’s business shifted to 80% pine and 20% hardwood and here’s why,” said the former employee, a mechanical engineer by training. “Let’s unravel the [Enviva] myth. You’re not getting free scraps or tree limbs; you’re buying whole trees. And hardwood costs a lot of money. Also, the thermal value of pine (how much heat it produces when burned) is higher and it’s cheaper to buy.

“But the wood scientists at the company should have known that there is pitch and resin in pine. It’s not environmentally friendly during processing; it releases a lot of on-site air pollution. But significantly for us maintaining the machines, pine is corrosive to anything but stainless steel. And all of our equipment is made out of carbon steel,” which degrades and rusts quickly when exposed to moisture.

If Enviva had been processing mostly hardwood trees into pellets, its manufacturing operations may have held up better, keeping down manufacturing costs of pellets per ton. But its pellet-making machinery, at least in Virginia and North Carolina, being made from carbon steel, while far less expensive to install than stainless steel, couldn’t hold up under the strain of nonstop production demands.

“I couldn’t believe what I was seeing,” the former maintenance manager said. “The carbon steel chains and conveyors were being sandblasted away by all the pine that was going through it. Look, these chains and conveyors are gigantic, and all this equipment is just rotting away because it’s made out of the wrong material. You can’t really repair it; you should replace it. But that’s too expensive. So, you patch it up until it breaks down again. Repairs would range from $700,000 to $1 million — just to patch things up for a while.”

Thus, higher wood-procurement expenses, coupled with expensive equipment breakdowns and repairs, have both reduced output and driven up pellet making costs. This combination turned Enviva’s profits to losses for years on contracts with fixed sale prices per ton of pellets, the former employee said.

In its SEC filing on Nov. 9, Enviva wrote that $21.1 million of its $85.2 million in third quarter losses, or 25%, was attributed to “asset impairments,” which in accounting jargon means damaged equipment and machinery.

The company also noted that its survival is based in part on “our ability to renegotiate customer contracts.”

A loaded logging truck pulls into the Enviva biomass wood pellet plant in Northampton, North Carolina. Image courtesy of the Dogwood Alliance/NRDC.

A loaded logging truck pulls into the Enviva biomass wood pellet plant in Northampton, North Carolina. Image courtesy of the Dogwood Alliance/NRDC.

In the spring of 2019, investigators tracked logging trucks coming from a mature hardwood forest and going to Enviva’s Northampton, North Carolina, facility. The clear-cut, seen here, was located in the Tar-Pamlico River Basin, alongside Sandy Creek, feeding into the Pamlico Sound of North Carolina. Image courtesy of the Dogwood Alliance.

In the spring of 2019, investigators tracked logging trucks coming from a mature hardwood forest and going to Enviva’s Northampton, North Carolina, facility. The clear-cut, seen here, was located in the Tar-Pamlico River Basin, alongside Sandy Creek, feeding into the Pamlico Sound of North Carolina. Image courtesy of the Dogwood Alliance.

Hanging global questions

Forest advocates — who have long decried the stark contrast between Enviva’s forest-friendly claims and its contributions to deforestation during a climate emergency, celebrated the company’s crisis and said they weren’t surprised by it.

“Enviva built a business model based on environmental injustice [and] forest destruction,” the North Carolina-based Dogwood Alliance, an NGO, said in a statement. “The [wood pellet] industry operates on a model of greenwashing, bad climate science, large-scale clearcutting and cutting corners on community protections.”

Many questions remain. In 2023, U.S. wood pellet exports were up 6% through September over last year’s record shipments, according to the U.S. Department of Agriculture. But if Enviva, its 10 plants and the 6 million metric tons of pellets it ships to the U.K., EU and Asia vanishes, who if anyone will fill the gap? If Enviva plants in Virginia and North Carolina remain in the same poor condition as the former employee knew them to be, do they hold much, if any, resale value?

U.K.-based Drax, one of Enviva’s biggest customers, which also has profitable pellet mills in the Deep South, did not respond to questions from Mongabay. Japanese companies Sumitomo and Mitsubishi Corporation are big Enviva customers. But there is no evidence that either is willing to extend a financial lifeline to Enviva or take over its operations.

Fenna Swart, a forest advocate with the Clean Air Committee in the Netherlands, has helped coordinate opposition to EU wood pellet imports and subsidies. She told Mongabay she sees Enviva’s possible downfall as a potential incentive to move away from forest biomass as an energy source.

“If Enviva indeed fails to load the bulk carriers to Europe with tons of crushed forests, the EU, and the Netherlands in particular, are expected to seize the opportunity to accelerate the phasing out of [forest biomass for energy] subsidy flows,” said Swart, referring to the billions of dollars paid annually by the EU to subsize wood pellet purchases. “In addition to the decision of the Dutch government last year to immediately stop all subsidies for new biomass projects, this will also limit long-term subsidies.

“We know that EU biomass from [manufacturer] Graanul Invest [in the Baltic states] has been limited since the Ukrainian war,” Swart noted. “With Enviva falling short, if this [trending] development continues, European governments will ideally focus more on [natural] gas as a transition fuel and redirect biomass subsidies to real forms of sustainable energy such as hydrogen and investment in energy savings.”

Banner image: Enviva has long claimed that it uses mostly wood scraps and treetops for its pellets. That’s clearly not true as evidenced by this aerial view showing a massive ring of thousands of whole trees at Enviva’s Sampson County, North Carolina, forest biomass facility. Most wood pellets made in the U.S. are shipped to Europe. Image courtesy of the Dogwood Alliance.

Justin Catanoso, a regular contributor to Mongabay, is a professor of journalism at Wake Forest University in North Carolina.